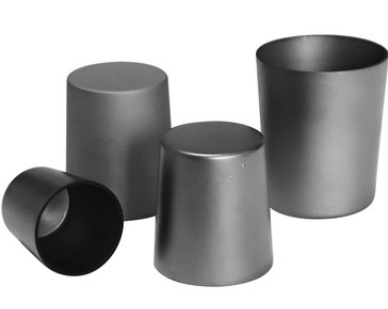

Pyrolytic Graphite Crucible

| Product | Pyrolytic Graphite Crucible (PG Crucible) |

| Part Number | PG01 |

About Pyrolytic Graphite (PG) Crucible

Pyrolytic Graphite (PG) is a new type of carbon material. It is a kind of pyrolytic carbon with high crystalline orientation, which is deposited by chemical vapor deposition (CVD) on the graphite substrate at 1800°C – 2000°C under certain furnace pressure. It has high density (2.20 g/cm3), high purity (impurity content 0.0002%) and anisotropy of thermal, electrical, magnetic and mechanical properties. The vacuum of 10 mmHg can be maintained at about 1800°C.

Pyrolytic Graphite is a kind of carbon material on which hydrocarbon gas decomposes and deposits on the surface of hot solid. It is not real graphite but carbon material. Generally speaking, the carbon deposited above 1800°C is called pyrolytic graphite, and the carbon deposited below 1800°C is pyrolytic carbon.

The microstructure of pyrolytic graphite is mainly affected by deposition temperature and surface roughness of matrix. The round and uneven state can be seen on the deposition surface.

It is very stable to water, organic solvents and most acids and bases, but it is easy to act on chromic acid and chloric acid solution, concentrated sulfuric acid and concentrated nitric acid.

NCE can provide Pyrolytic Graphite (PG) Crucibles as required. Various sizes can be customized. Please contact us for more details. Get a Quote Now! For other ceramic materials, please check our Ceramics catalog page.

Pyrolytic Graphite (PG) Production

Pyrolytic graphite crucible (about 2000°C) was used to decompose and polymerize hydrocarbons in a vacuum inert atmosphere to produce huge aromatic hydrocarbons, which were then deposited on the surface of high purity graphite matrix material and then made by dehydrogenation and recrystallization.

Raw material

Hydrocarbons in the gaseous or liquid state. For example, methane, acetylene, propane, natural gas, benzene and toluene can be used as raw materials for carbon deposition. The carrier gas or diluent gas includes inert gases such as nitrogen and argon. The matrix is refractory metal and its compound, artificial graphite, which is usually used.

Process parameters

The specific parameters are determined by experiments according to the size of the deposition furnace. The deposition temperature, furnace pressure and gas flow rate have a decisive influence on the quality of the product.

Heating Mode

It can be divided into direct heating method and indirect heating method.

By direct heating, the substrate itself is electrified to produce high temperature. This method is suitable for parts with thin sedimentary body, simple shape and small volume. It is suitable for research work.

In the indirect heating method, the substrate is placed inside or outside the heating body and heated to a high temperature by the radiation of the heating body. This heating method can be used in resistance heating and induction heating. This method, especially induction heating, is more suitable for making parts with large size, large thickness and complex shape.

Typical application of Pyrolytic Graphite (PG)

Pyrolytic graphite is used in throat liner of rocket nozzles, antimagnetic balls for satellite attitude controls, electron tube grids, crucibles for smelting high purity metal, brushes for voltage regulators, discharge chambers of laser, insulation material for high temperature furnaces, and epitaxial wafers for semiconductor production.

Pyrolytic Graphite (PG) Crucible Typical Dimensions

| Item No | Volume |

| PG01-10 | 10 ml |

| PG01-20 | 20 ml |

| PG01-30 | 30 ml |

| PG01-50 | 50 ml |

* This form is for typical sizes. Other sizes are customizable.

Pyrolytic Graphite (PG) Typical Specification

| Properties | Units | Values |

| Density | g/cm3 | 2.15-2.22 |

| Bending Strength | MPa | 116 |

| Tensile Strength | MPa | 80 |

| Thermal Conductivity | W/m°C | “ab” 382, “c” 2.8 |

| Resistivity | Ω·cm | “ab” 2×10-4 “c” 0.6 |

Order Information

Inquiries and orders should include the following information:

- Quantity

- Dimensions or drawings

Packing and Storage

Standard Packing: Sealed bags in carton boxes. Special package is available on request.