Multi-Walled Carbon Nanotubes

| Product | Multi-Walled Carbon Nanotubes (MWCNT’s) |

| Part Number | CNT-MWCNT |

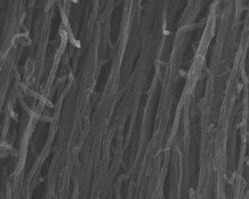

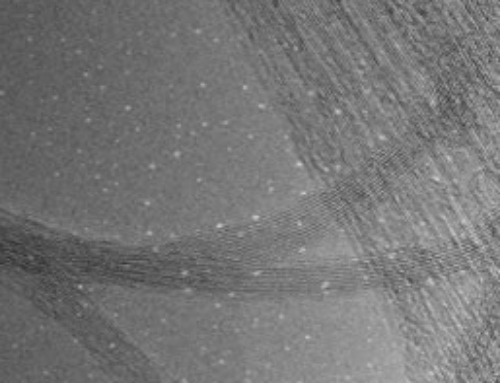

Carbon nanotubes (CNT’s) can be divided into single-walled carbon nanotubes (SWCNT’s) and multi-walled carbon nanotubes (MWCNT’s) according to the number of graphene sheets. At the beginning of the formation of MWCNT’s, it is easy to form trap centers between layers to capture various defects. Therefore, the wall of multi-wall tubes is usually filled with small hole like defects. Compared with the multi-wall tube, the single wall tube has smaller distribution range, fewer defects, and higher uniformity. The typical diameter of single wall tube is 0.6-2 nm. The innermost layer of multi-wall tube can reach 0.4 nm and the coarsest can reach hundreds of nanometers. But the typical diameter is 2-100 nm.

CNT’s have good mechanical properties. The tensile strength of CNT’s reaches 50-200 GPA, which is 100 times of that of steel. But its density is only 1/6 of that of steel, which is at least one order of magnitude higher than that of conventional graphite fiber. Its elastic modulus can reach 1 TPA, which is equivalent to that of diamond, about 5 times that of steel. The tensile strength of carbon nanotubes with ideal structure is about 800 GPa. Although the structure of carbon nanotubes is similar to that of polymer materials, its structure is much more stable than that of polymer materials. Carbon nanotubes are the materials with the highest specific strength that can be prepared at present. If other engineering materials are used as the matrix together with carbon nanotubes to make composite materials, the resulting composite materials will show good strength, elasticity, fatigue resistance and isotropy, which will greatly improve the properties of the composite materials.

Carbon nanotubes have the same hardness as diamond, but they have good flexibility and can be stretched. Among the commonly used reinforced fibers in industry, the ratio of length to diameter is a key factor to determine the strength. The length diameter ratio that material engineers hope to get is at least 20:1, while the aspect ratio of carbon nanotubes is generally more than 1000:1, which is an ideal high strength fiber material.

High purity MWCNT’s: High purity MWCNT’s can be divided into CNT102-107 according to their diameters. There are also hydroxylated MWNT’s CNT202-207, carboxylated MWCNT’s CNT302-307, short MWCNT’s, carboxylated MWNT’s, graphitized MWNT’s, etc. Special carbon nanotube products include: carbon nanotube arrays, aminated carbon nanotubes, nickel plated carbon nanotubes, carbon nanofibers, etc.

NCE can provide various CNT’s with different sizes available on request. Please contact us for more details. Get a Quote Now! For other sputtering targets, please check our Carbon Materials catalog page.

Typical Applications:

Carbon nanotubes can be made into transparent and conductive films to replace ITO (indium tin oxide) as the material of touch screen.

Typical Specification

MWCNT

| Item Code | OD (nm) | Length (µm) | Purity (%) | Specific Surface Area (m2/g) | Bulk Density g/cm3 | Conductivity EC (s/cm) |

| CNT102 | <8 | 10-30 | >98% | >500 | 0.27 | >150 |

| CNT103 | 8-15 | 50 | >98% | >233 | 0.27 | >150 |

| CNT104 | 10-20 | 10-30 | >98% | >200 | 0.27 | >150 |

| CNT105 | 20-30 | 10-30 | >98% | >110 | 0.22 | >150 |

| CNT106 | 30-50 | 10-20 | >98% | >60 | 0.22 | >150 |

| CNT107 | >50 | 10-20 | >98% | >40 | 0.18 | >150 |

Hydroxylated MWNTs:

| Item Code | OD (nm) | Length (µm) | Purity (%) | Specific Surface Area (m2/g) | Bulk Density g/cm3 | Conductivity EC (s/cm) | -OH (wt%) |

| CNT202 | <8 | 10-30 | >98% | >500 | 0.27 | >150 | 5.58 |

| CNT203 | 8-15 | 50 | >98% | >233 | 0.27 | >150 | 3.7 |

| CNT204 | 10-20 | 10-30 | >98% | >200 | 0.27 | >150 | 3.06 |

| CNT205 | 20-30 | 10-30 | >98% | >110 | 0.22 | >150 | 1.76 |

| CNT206 | 30-50 | 10-20 | >98% | >60 | 0.22 | >150 | 1.06 |

| CNT207 | >50 | 10-20 | >98% | >40 | 0.18 | >150 | 0.71 |

Carboxylated MWCNTs:

| Item Code | OD (nm) | Length (µm) | Purity (%) | Specific Surface Area (m2/g) | Bulk Density g/cm3 | Conductivity EC (s/cm) | -COOH (wt%) |

| CNT302 | <8 | 10-30 | >98% | >500 | 0.27 | >150 | 3.86 |

| CNT303 | 8-15 | 50 | >98% | >233 | 0.27 | >150 | 2.56 |

| CNT304 | 10-20 | 10-30 | >98% | >200 | 0.27 | >150 | 2.00 |

| CNT305 | 20-30 | 10-30 | >98% | >110 | 0.22 | >150 | 1.23 |

| CNT306 | 30-50 | 10-20 | >98% | >60 | 0.22 | >150 | 0.73 |

| CNT307 | >50 | 10-20 | >98% | >40 | 0.18 | >150 | 0.43 |

Order Information

Inquiries and orders should include the following information:

- Quantity

- Dimension

- Others if required

Packing and Storage

Standard Packing: Packed in sealed bags with labels. Items will be packed properly to avoid damage during transit.

Storage: Store in dry environment, sealed packages. Handle with care, prevent pressure and collision.