Lithium Iron Phosphate Sputtering Target

| Product | Lithium Iron Phosphate Sputtering Target (LiFePO4 Target) |

| Part Number | SP22-09 |

| CAS Number | 15365-14-7 |

Lithium Iron Phosphate (LiFePO4) is a new generation of lithium battery cathode material, a new generation of lithium ion materials developed after LiCoO3, LiMn2O4 and other ternary materials. LiFePO4 cathode material has the advantages of good safety performance, long service life, high current charging and discharging, etc., which makes up for the serious shortcomings of other lithium batteries. Among the existing battery materials, LiFePO4 cathode material is more suitable for large-scale power batteries and energy storage batteries. With the development of new energy technology, LiFePO4 cathode material will play an important role.

NCE can offer the Lithium Iron Phosphate (LiFePO4) Sputtering Target with different sizes available on request. Please contact us for more details. Get a Quote Now! For other sputtering targets, please check our Sputtering Targets catalog page.

Trade Name: lithium iron phosphate carbon coated, lithium iron phosphate, ferrous lithium phosphate, iron lithium phosphate, lithium iron(II) phosphate, triphylite, lithium iron(II) phosphate powder

Typical Applications:

Lithium Iron Phosphate (LiFePO4) is widely used in the lithium battery industry. It can also be used for the scientific experiments or research applications, etc.

Typical Specification

| Material: | Lithium Iron Phosphate (LiFePO4) |

| Purity: | 99.95% |

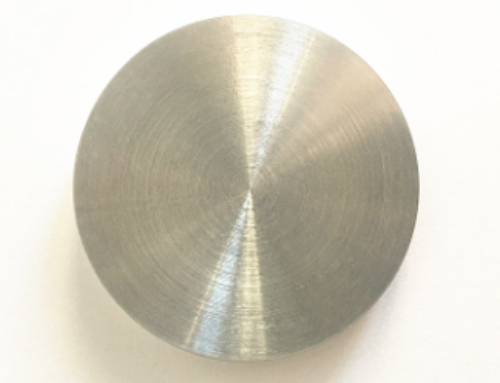

| Type: | Planar Target |

| Shape: | Discs, plates, or custom work |

| Typical Dimension: | Diameter: 1”, 2”, 3”, 4”; Thickness: 0.125”, 0.2”, 0.25” |

| Bonding (recommended): | Elastomer, Indium |

∗ Custom work dimensions or special requirements are available.

Order Information

Inquiries and orders should include the following information:

- Quantity

- Dimensions or drawings

- Bonding service or not (bonding recommended)

Packing and Storage

Standard Packing: Packed in sealed bags with labels. Items will be packed properly to avoid damage during transit.

Storage: Store in dry environment, sealed packages. Handle with care, prevent pressure and collision.

Note:

- Before using, observe whether the surface is clean. Wear clean gloves to operate. Avoid direct contact with materials by hand and avoid contamination by oil and other things.

- Indium bonding: max. operating temperature 150°C; Elastomer bonding: max. operating temperature 250°C.