Indium Tin Oxide Sputtering Target

| Product | Indium Tin Oxide Sputtering Target (ITO Target) |

| Part Number | SP49-02 |

| CAS Number | 50926-11-9 |

Indium tin oxide (ITO, or tin doped indium oxide) is a mixture of indium (III) oxide (In2O3) and tin (Group IV) oxide (SnO2). The typical ratio is 90% In2O3 and 10% SnO2, and other ratios such as 93%/7%, 95%/5% or 97%/3% are available on request.

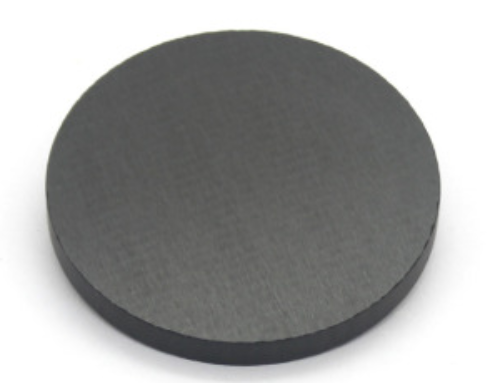

Indium tin oxide (ITO) target is suitable for the production of flat-panel liquid crystal displays. When it is thin film, it is transparent and slightly brown. In the block state, it is yellow to gray.

The main characteristic of indium tin oxide is the combination of electrical conduction and optical transparency. However, compromises need to be made in film deposition because high concentration of charge carriers will increase the conductivity of the material, but reduce its transparency.

Indium tin oxide films are usually deposited on the surface by physical vapor deposition or some sputtering deposition techniques.

NCE can offer the high quality indium tin oxide (ITO), zinc oxide (ZnO), zinc aluminum oxide (AZO), zinc gallium oxide (GZO), zinc indium oxide (IZO) series special test targets for transparent conductive films. Sputtering targets with different sizes available on request. Please contact us for more details. Get a Quote Now! For other sputtering targets, please check our Sputtering Targets catalog page.

Typical Applications:

ITO is mainly used for making liquid crystal displays, flat panel displays, plasma displays, touch screens, electronic paper, organic light emitting diodes, solar cells, anti-static coating and EMI shielding transparent conduction coating.

ITO is also used in various optical coatings. The most notable are infrared reflection coating (thermal mirror), automobile, and sodium vapor lamp glass in architecture. Other applications include gas sensors, anti reflective films, and Bragg reflectors for VCSEL lasers.

ITO thin film stress gauges can be used in environments above 1400°C and severe conditions, such as gas turbines, jet engines, and rocket engines.

Typical Specification

| Material: | Indium oxide (In2O3)/Tin Oxide(SnO2) |

| Content: | 90:10, 93:7, 95:5, 97:3 |

| Relatively Density: | ≥99.5% |

| Purity: | 99.99% |

| Shape: | Discs, plates, step targets, custom work |

| Typical Dimension: | Diameter: 1”, 2”, 3”, 4”; Thickness: 0.125”, 0.2”, 0.25” |

| Bonding (recommended): | Elastomer, Indium |

∗ Special requirements are available. Please review the sputtering gun manual to confirm the target shape and size.

Order Information

Inquiries and orders should include the following information:

- Quantity

- Dimensions or drawings

- Bonding service or not (bonding recommended)

Packing and Storage

Standard Packing: Packed in sealed bags with labels. Items will be packed properly to avoid damage during transit.

Storage: Store in dry environment, sealed packages. Handle with care, prevent pressure and collision.

Note:

- Before using, observe whether the surface is clean. Wear clean gloves to operate. Avoid direct contact with materials by hand and avoid contamination by oil and other things.

- Indium bonding: max. operating temperature 150°C; Elastomer bonding: max. operating temperature 250°C.

Physical Properties

| Symbol: | ITO |

| Color: | Black |

| Melting Point: | 1800°C |

| Density: | 7.14 g/cm3 |