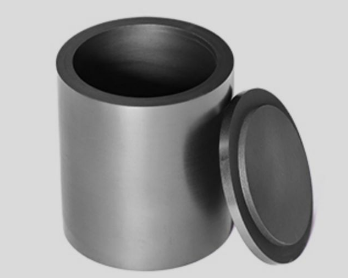

Graphite Crucible

| Product | Graphite Crucible |

| Part Number | GC |

About Graphite Crucible

Graphite crucibles are a kind of crucibles made of graphite, clay, silica and wax stones. Graphite crucibles are mainly used for smelting copper, brass, gold, silver, zinc, lead, niobium, and other non-ferrous metals and their alloys.

The Graphite Crucible is made of natural flake graphite as the main raw material and plastic refractory clay or carbon as binder. It has the characteristics of high temperature resistance, strong thermal conductivity, good corrosion resistance and long service life. In the process of high temperature use, the coefficient of thermal expansion is small, and it has a certain anti-strain performance for rapid cooling and rapid heating. It has strong corrosion resistance to acidic and alkaline solutions, excellent chemical stability, and does not participate in any chemical reaction in the smelting process. The inner wall of the graphite crucible is smooth, and the molten metal liquid is not easy to leak and adhere to the inner wall of the crucible, so that the metal liquid has good fluidity and castability, which is suitable for various mold casting. Because of the above excellent characteristics, graphite crucible is widely used in smelting alloy tool steel and nonferrous metals and their alloys.

NCE can provide Graphite Crucibles as required. Various sizes can be customized. Please contact us for more details. Get a Quote Now! For other ceramic materials, please check our Ceramics catalog page.

Graphite Crucible Typical Dimensions

| Item Code | OD (mm) | ID (mm) | Height (mm) | Depth (mm) | Volume |

| GC-1 | 20 | 14 | 20 | 16 | 2 ml |

| GC-2 | 25 | 19 | 25 | 21 | 5 ml |

| GC-3 | 30 | 22 | 30 | 25 | 9 ml |

| GC-4 | 30 | 22 | 60 | 55 | 20 ml |

| GC-5 | 30 | 22 | 80 | 75 | 28 ml |

| GC-6 | 30 | 22 | 100 | 95 | 36 ml |

| GC-7 | 30 | 22 | 120 | 112 | 42 ml |

| GC-8 | 35 | 25 | 35 | 30 | 14 ml |

| GC-9 | 40 | 30 | 40 | 35 | 24 ml |

| GC-10 | 40 | 30 | 80 | 75 | 50 ml |

| GC-11 | 40 | 30 | 100 | 95 | 65 ml |

| GC-12 | 40 | 30 | 120 | 112 | 79 ml |

| GC-13 | 50 | 40 | 50 | 45 | 56 ml |

| GC-14 | 50 | 40 | 80 | 75 | 94 ml |

| GC-15 | 50 | 40 | 100 | 95 | 119 ml |

| GC-16 | 50 | 40 | 120 | 112 | 140 ml |

| GC-17 | 60 | 50 | 60 | 55 | 107 ml |

| GC-18 | 60 | 50 | 80 | 75 | 140 ml |

| GC-19 | 60 | 50 | 100 | 95 | 186 ml |

| GC-20 | 60 | 50 | 120 | 112 | 219 ml |

| GC-21 | 70 | 55 | 100 | 90 | 210 ml |

| GC-22 | 70 | 55 | 120 | 110 | 250 ml |

| GC-23 | 75 | 60 | 100 | 90 | 254 ml |

| GC-24 | 85 | 70 | 110 | 100 | 384 ml |

| GC-25 | 100 | 80 | 120 | 110 | 552 ml |

| GC-26 | 120 | 100 | 140 | 130 | 1020 ml |

* This form is for typical sizes. Other sizes are customizable.

Order Information

Inquiries and orders should include the following information:

- Quantity

- Dimensions or drawings

Packing and Storage

Standard Packing:

Sealed bags in carton boxes. Special package is available on request.

Cautions:

Graphite crucibles should be protected from moisture. They are most afraid of moisture, which has a great impact on the quality of the crucibles. If the crucibles are used with moisture, they will break, burst, and the side and bottom will fall apart, resulting in the loss of molten metal, and even industrial accidents. Therefore, the graphite crucibles in the storage and use process must be kept from moisture.

The warehouses for storing graphite crucibles should be dry and ventilated, and the temperature should be kept between 5°C and 25°C. The relative humidity should be 50-60%. The crucibles should not be stored on brick soil or cement floor. Bulk graphite crucibles should be placed on wooden racks, 25-30 cm above the ground.

Graphite crucibles should not be placed on cold metal tables immediately after heating to avoid their rupture due to rapid cooling.