Copper Sputtering Target

| Product | Copper Sputtering Target (Cu Target) |

| Part Number | SP29-1 |

| CAS Number | 7440-50-8 |

Copper, a non-ferrous metal, is widely used in electrical, light industry, machinery manufacturing, construction, national defense industry and other fields. The results show that 6N copper softens at about 350 K and 4N copper softens at 440 K. Copper is not easily oxidized in dry air. But in humid air containing CO2, the surface and CO2 in air form a layer of toxic basic copper carbonate (copper green), which protects copper from CO2 corrosion. When heated in air, the surface will form black copper oxide with O2. Copper is not easy to be dissolved in hydrochloric acid or dilute sulfuric acid, but it can be dissolved in nitric acid with oxidation effect or hydrochloric acid containing oxidant. It is also soluble in ammonia water. The thermal conductivity of 6N copper is 3.0×104 w/(m·K) at 8 K, and that of 4N copper is 3.1×103 w/(m·K) at 18 K. High purity copper has excellent processability.

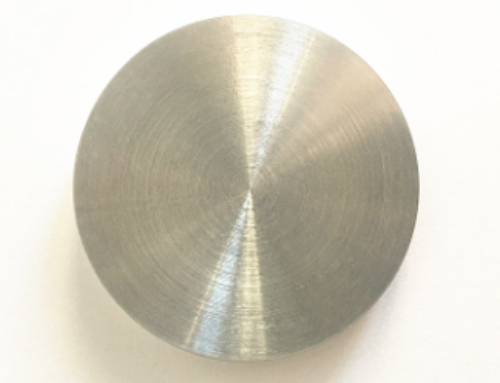

Copper sputtering target (Cu target) we can produce is with purity of 99.9% – 99.9999% and the minimum oxygen content can be less than 1 ppm. It is mainly used in display and touch screen wiring and its protective film, solar light absorption layer, semiconductor wiring and other industries. In addition to meeting the customer’s demand for planar targets (the largest G8.5 generation), we can also produce copper rotary targets, mainly used in the touch screen industry. It is difficult to break the grains of high-purity copper targets. We have to control the growth of twinning crystal by ultra large deformation to obtain fine and uniform microstructure, so as to ensure a lower erosion rate and reduce the sensitivity of particles formation in the sputtering process.

NCE can provide the Copper Sputtering Target with different sizes available on request. The impurities in copper sputtering target will reduce the conductivity of the materials. Impurity elements are the main factors affecting the yield in the production of semiconductor film. Impurities in the form of titanium, phosphorus, calcium, iron, chromium and selenium are particularly critical, and these metals are rarely found in our copper targets. Please contact us for more details. Get a Quote Now! For other sputtering targets, please check our Sputtering Targets catalog page.

Typical Applications:

The Copper Sputtering Target is mainly used in display and touch screen wiring and its protective film, solar light absorption layer, semiconductor wiring and other industries.

Typical Specification

| Material: | Copper (Cu) |

| Purity: | 99.9%, 99.99%, 99.999%, 99.9999% |

| Sputter: | DC sputtering |

| Type: | Planar target/rotary target |

| Shape: | Discs, plates, step targets, tubes, custom work |

| Typical Dimension: | Diameter: 1”, 2”, 3”, 4”; Thickness: 0.125”, 0.2”, 0.25” |

∗ Custom-work dimensions or special requirements are available.

Order Information

Inquiries and orders should include the following information:

- Quantity

- Dimensions or drawings

- Purity

Packing and Storage

Standard Packing: Packed in sealed bags with labels. Items will be packed properly to avoid damage during transit.

Storage: Store in dry environment, sealed packages. Handle with care, prevent pressure and collision.

Note: Before using, observe whether the surface is clean. Wear clean gloves to operate. Avoid direct contact with materials by hand and avoid contamination by oil and other things.

Physical Properties

| Symbol: | Cu |

| Color: | Purplish red |

| Melting Point: | 1084.62°C |

| Boiling Point: | 2562°C |

| Density: | 8.92 g/cm3 |

| Melting Heat: | 13.26 kJ·mol-1 |

| Heat of Vaporization: | 300.4 kJ·mol-1 |

| Specific Heat Capacity: | 24.86 J·mol-1·K-1 |

| Thermal Conductivity: | 401 w·M-1·K-1 |