Copper Indium Gallium Sputtering Target

| Product | Copper Indium Gallium Sputtering Target |

| Part Number | SP29-3 |

| Synonyms | CuInGa Target, CIG Target |

Copper Indium Gallium (CIG) Alloy, is also called CuInGa. It is one of the important materials for CIGS thin film battery.

Copper indium gallium selenium (CIGS) thin film solar cells have the characteristics of stable performance, strong radiation resistance and relatively high photoelectric conversion efficiency. At present, CIGS thin film solar cells are the first of all kinds of thin film solar cells, with a conversion efficiency close to that of crystalline silicon solar cells. They are the mainstream products in the market, but the cost is only 1/3. Because of their excellent performance, they are called the next generation of low-cost solar cells in the world.

NCE provides various Copper Indium Gallium (CuInGa, CIG) Sputtering Target with different proportions by vacuum melting method, and can also produce copper indium gallium rotary targets by smelting method according to the needs of large-scale production of customers (with the advantages of high density and low gas content). Various sizes are available on request. Please contact us for more details. Get a Quote Now! For other sputtering targets, please check our Sputtering Targets catalog page.

Typical Applications:

Copper Indium Gallium (CIG) Sputtering Target has a broad market prospect in the application of solar power generation on the ground or in the power supply of space micro satellites.

Typical Specification

| Material: | Copper Indium Gallium (CuInGa) |

| Typical: | CuInGa |

| Purity: | 99.99% |

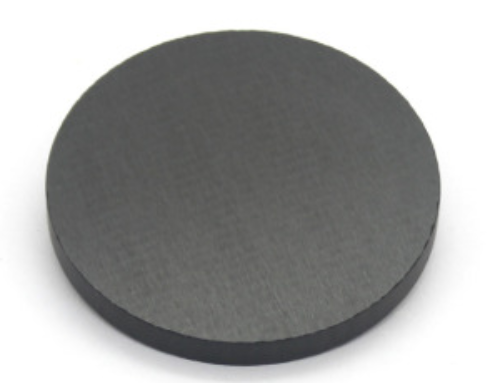

| Type: | Planar target, rotary target |

| Shape: | Discs, plates, step targets, custom work |

| Typical Dimension: | Diameter: 1”, 2”, 3”, 4”; Thickness: 0.125”, 0.2”, 0.25” |

| Bonding Service: | Optional |

∗ Custom-work dimensions or special requirements are available.

Order Information

Inquiries and orders should include the following information:

- Quantity

- Dimensions or drawings

Packing and Storage

Standard Packing: Packed in sealed bags with labels. Items will be packed properly to avoid damage during transit.

Storage: Store in dry environment, sealed packages. Handle with care, prevent pressure and collision.

Note:

- Before using, observe whether the surface is clean. Wear clean gloves to operate. Avoid direct contact with materials by hand and avoid contamination by oil and other things.

- Indium bonding: max. operating temperature 150°C; Elastomer bonding: max. operating temperature 250°C.