Cobalt Powder (Co Powder)

| Product | Cobalt Powder (Co Powder) |

| Part Number | ME27 |

| Purity | 97.9%~99.9% min |

| Density | 8.9 g/cm3 |

| CAS# | 7440-48-4 |

Cobalt (Co) is a lustrous steel gray metal, which is hard and brittle, ferromagnetic. When heated to 1150°C, its magnetism disappears. When heated to over 300°C in air, Co is oxidized to form CoO, which is burned to Co3O4 in white heat. Cobalt is an important raw material for the production of heat-resistant alloy, hard alloy, anticorrosive alloy, magnetic alloy, and various cobalt salts.

Typical applications:

Cobalt based alloy or cobalt containing alloy steel is used in blades, impellers, guide pipes, jet engines, rocket engines, missile parts of gas turbines, high load heat-resistant parts of chemical equipment and important metal materials of atomic energy industry.

As a binder in powder metallurgy, Co can ensure the toughness of cemented carbide. It is also an important part of permanent magnetic alloy. In the chemical industry, it is not only used in superalloy and anticorrosive alloy, but also in colored glass, pigment, enamel, catalyst, desiccant, etc. The application of Co in battery industry, diamond tool industry and catalyst industry will be further expanded.

There are four typical cobalt powder specifications: nearly spherical cobalt powder, short-rod shaped cobalt powder, granulated cobalt powder, and single crystal cobalt powder (can be customized with special specifications).

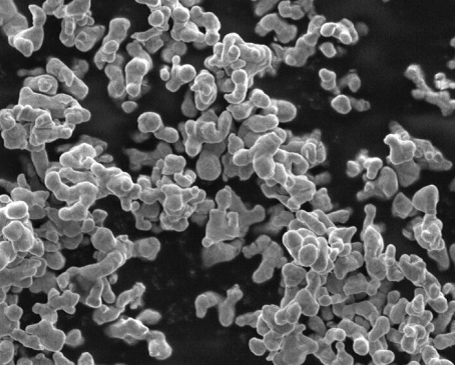

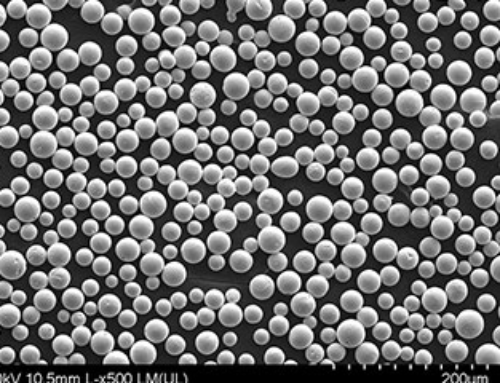

1. Nearly Spherical Co Powder

Feature: The microstructure is similar to a sphere and could be uniform mixed with WC powder.

Application: Bars; Drills; Finished carbide products such as cutting tools and battery materials.

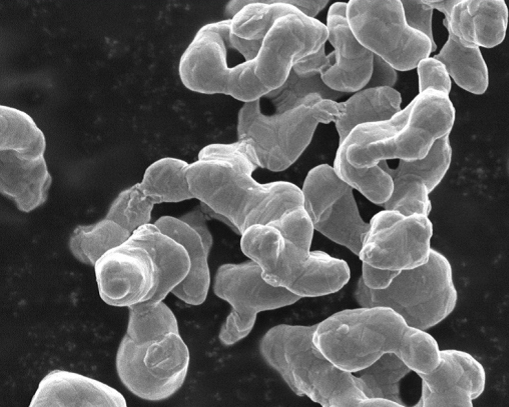

2. Short-rod shaped Co Powder

Feature: Compared with the traditional fibrous Co powder, the mixing effect and wettability with WC is obvious an advantage to other products, which can effectively avoid the cobalt pool phenomenon and improve the hardness and bending strength of the ordinary cemented carbide product.

Application: alloy for gravity cutting or heavy cutting, mining tools, battery materials, magnetic materials.

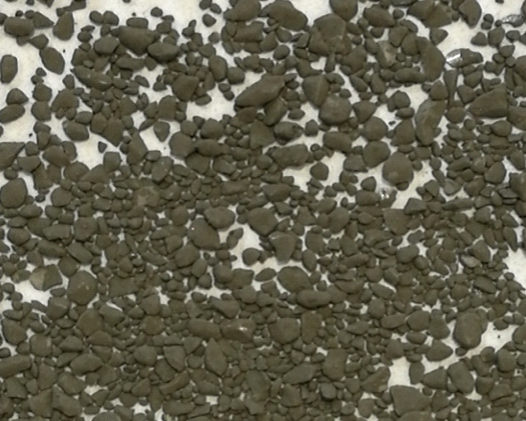

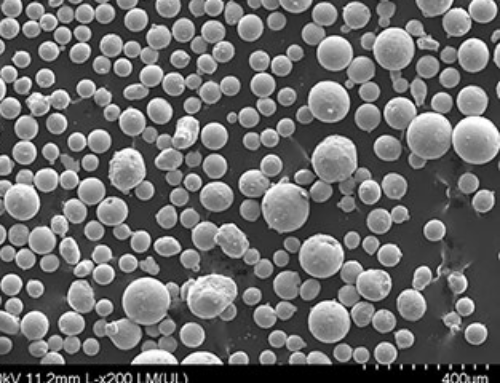

3. Granulated Co Powder

Feature: Granular paraffin-coated spherical cobalt powder with good fluidity and no dust.

Application: diamond tool, rope tool, etc.

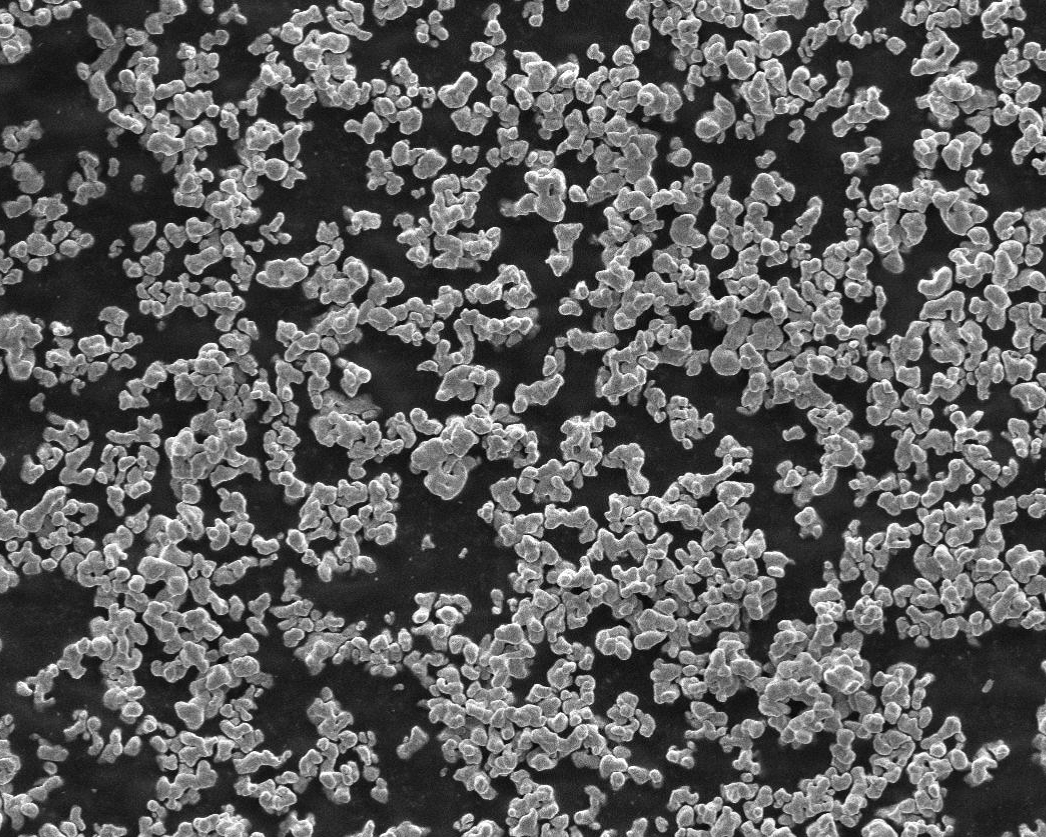

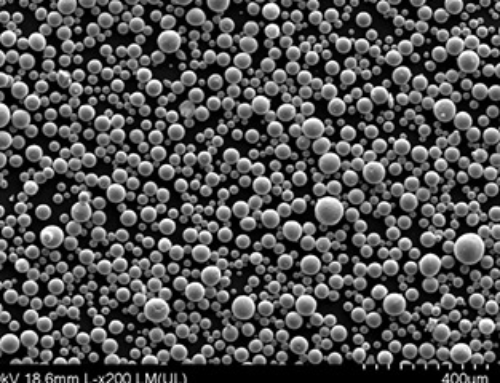

4. Single Crystal Co powder

Feature: The microstructure is similar to a sphere with good dispersity. Also the particle size is narrow distribution with single crystal type.

Application: diamond tool, rope tool, etc.

NCE provides high quality Cobalt (Co) Powder with various particle shapes and sizes. Please contact us for more details. Get a Quote Now! Related product: Spherical Cobalt (Co) Powder. For other metal materials, please check our Metals/Precious Metals catalog page.

Typical Specification

| Item Code | Type | Co (%) | FSSS (μm) | D50 (μm)≤ | Apparenet Density (g/cm3) | |

| ME27-T1 | Nearly Spherical | Coarse | 99.9 min. | >2.0 | 30 | 0.80-2.30 |

| ME27-1 | Regular | 1.51-2.0 | 15 | 0.70-1.20 | ||

| ME27-2 | 1.01-1.50 | 10 | 0.60-1.00 | |||

| ME27-3 | Fine | 0.81-1.00 | 8 | 0.60-0.80 | ||

| ME27-4 | 0.60-0.80 | 7 | 0.50-0.80 | |||

| ME27-5 | Sub-Micro | 0.40-0.60 | 5 | 0.50-0.80 | ||

| ME27-6 | Single Crystal | 1.01-1.50 | 10 | 1.05-1.30 | ||

| ME27-2 | Short-Rod Shaped | 1.01-1.50 | 10 | 0.60-1.00 | ||

| ME27-W | Granulated | 97.9 | 1.01-1.50 | 10 | 0.60-1.00 | |

* Special requirements are available.

Order Information

Inquiries and orders should include the following information:

- Quantity

- Type/Application

- Particle Size

Packing and Storage

Standard Packing: Packed in Drums.

Special package is available on request.

Physical Properties – Cobalt Powder (Co Powder)

| Appearance Form | Powder |

| Color | Grey |

| Melting Point | 1495°C |

| Boiling Point | 2927°C |