Boron Nitride Crucible (BN Crucible)

| Product | Boron Nitride Crucible (BN Crucible) |

| Part Number | BN99 |

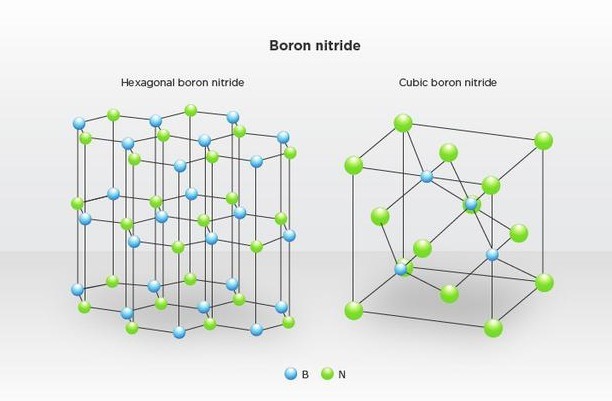

Boron nitride is a crystal composed of nitrogen and boron atoms. There are four different variants: hexagonal boron nitride (hBN), rhombohedral boron nitride (RBN), cubic boron nitride (CBN) and Wurtzite boron nitride (WBN).

The Boron nitride crucibles are made of boron nitride powder by hot pressing and sintering to form product blocks and then processed according to the size and specification required by customers. Boron nitride is also known as white graphite. Its structure is similar to that of graphite. It has the hexagonal structure, with theoretical density of 2.27g/cm3 and Mohs hardness of 2. It has good electrical insulation, thermal conductivity, excellent thermal shock resistance and chemical stability, and good moisture resistance for molten metal, slag and glass. Get a Quote Now! For other ceramic materials, please check our Ceramics catalog page.

Materials Suitable for Boron Nitride Crucibles

- Ferrous metals: iron, copper, aluminum, nickel, magnesium, bismuth, zinc, etc., alloy Fe Co Ni Si co Zr Nb;

- It does not react with water and acid at room temperature, and slowly hydrolyzes with water to generate boric acid and ammonia;

- Rare earth, nitride.

Materials NOT Suitable for Boron Nitride Crucibles

- Antimony oxide, chromium oxide, molybdenum oxide, arsenic trioxide, titanium carbide, etc.

- The melting of high lead glass glaze in 800-950°C air has erosion on BN, but there is no reaction under the protection of nitrogen or inert gas.

- Boron phosphate corrodes boron nitride in 1400°C nitrogen, and reacts with hot concentration or molten alkali and hot chlorine gas.

Precautions for Use of Boron Nitride Crucibles

- The service temperature in the air shall not exceed 900°C, or the contact surface between boron nitride and oxygen will be oxidized and peeled off.

- Boron nitride is easy to absorb moisture. The crucible cannot be stored in wet areas or washed with water. It can be directly wiped with sandpaper or alcohol.

Typical Application

Boron nitride crucible is mainly used for ceramic melting, silicate melting, metal smelting, crystal growth, etc.

Comparison with Graphite Crucibles and Alumina Crucibles

Compared with Graphite Crucible, Boron Nitride Crucible has the Following Advantages

- The chemical property is stable. It does not react with the melted metal, thus improves the purity.

- The oxidation resistance is better, 400-500°C higher than that of graphite.

- Long service life, not easy to crack. Good corrosion resistance and wear resistance.

- It is not easy to fall off the powder, and the pollution is small. The film has good properties.

- Can be processed into any shape and size needed;

- Good thermal conductivity, excellent thermal shock resistance, no cracking during sudden cooling and heat shock;

- Excellent electrical insulation performance. Even under high temperature conditions, it still has good insulation.

Compared with Alumina Crucibles, Boron Nitride Crucibles have the Following Advantages

- High temperature resistance, long-term use temperature 1800°C under vacuum, long-term use 2100°C under atmosphere protection. Alumina shall not exceed 1700 degrees.

- It has strong thermal shock resistance and does not crack when it is cold and hot. The boron nitride ceramics are taken out from the furnace at 1000°C and quenched by blowing. They will not crack even if they are repeatedly cooled for 100 times.

- It is resistant to acid and alkali corrosion, strong electrical insulation, and 3-4 times as strong as alumina.

- Boron nitride ceramics do not react with many metals, ceramics, rare earth and other materials. Such as ferrous metal, iron, copper, stainless steel, bismuth, aluminum, tin, chromium, lead, nickel, magnesium, etc., glass melt, sodium glass, cryolite, etc., silicon lava: slag, fluoride, etc. It can be used as a container, crucible, burning plate, etc.

Compared with Alumina Crucible, Boron Nitride Crucible have the Following Disadvantages

- The strength, hardness and wear resistance of boron nitride ceramics are lower than that of alumina, so it is not suitable for use in vibration friction environment.

- Boron nitride ceramics cannot be used in air at a temperature higher than 900°C, or it will be oxidized. Boron nitride can only be used at a temperature of 2200°C under the protection of vacuum or atmosphere.

Typical Specification

| Grade | BN99 | |

| Purity % | BN | 99% |

| Major Impurity | B2O3 | <0.50% |

| Structure | Hexagonal boron nitride (hBN) | |

| Density | 2 g/cm3 | |

| Hardness | 300 HL | |

| Flexural Strength | 3000 Psi | |

| Coefficient of Thermal Expansion | (25°C-1200°C) | -1~2.5 (10-6/K) |

| Thermal Conductivity | 50 W/mk | |

| Max operating Temperature | Atmosphere | 900°C |

| Vacuum | 1800°C | |

| Inert | 2100°C | |

| RT Resistivity | >1014 Ω⋅cm | |

Order Information

Inquiries and orders should include the following information:

- Quantity

- Dimensions or drawings

- With or without lids

Packing and Storage

Standard Packing: Sealed bags in Carton Box. Special package is available on request.